Condition-based maintenance

Overview: What is condition-based maintenance & why does it matter to customers?

Imagine a manufacturing plant where machines are constantly running. Traditionally, maintenance happens on a fixed schedule or when the machine breaks down. This often leads to wasted effort, unnecessary downtime, and sometimes even missed failures.

Condition-based maintenance (CBM) is a preventative maintenance approach that evaluates the real-time condition of assets to decide when maintenance should be performed. It uses real-time data from sensors, inspections, or diagnostics to detect signs of wear, degradation, or failure.

Problem: too much work being done manually, too many assets to monitor and not enough staff

Even with advanced maintenance software, many large companies still operate reactively—waiting for assets to fail before repairing them. This approach leads to costly downtime, often in the millions, and prevents technicians and reliability engineers from focusing on planned, high-value tasks. As a result, organizations incur significant financial and productivity losses.

Research goals

The project aimed to uncover user needs and challenges in CBM implementation while identifying opportunities to enhance customer value by providing better support throughout the process.

My Role & Teams involved

My role:

Creation of research plan

Creation of discussion guide

Participant recruitment through Userinterviews & Respondent

Analysis of interviews

Reporting and socialising research

Tools used:

Monday.com- project management platform

Userinterviews & Respondent for recruitment

MsTeams for research interviews

Mural for data analysis

Teams involved:

3 UX Researchers

1 UX Designer

1 Product manager

3 Developers

Participant interviews

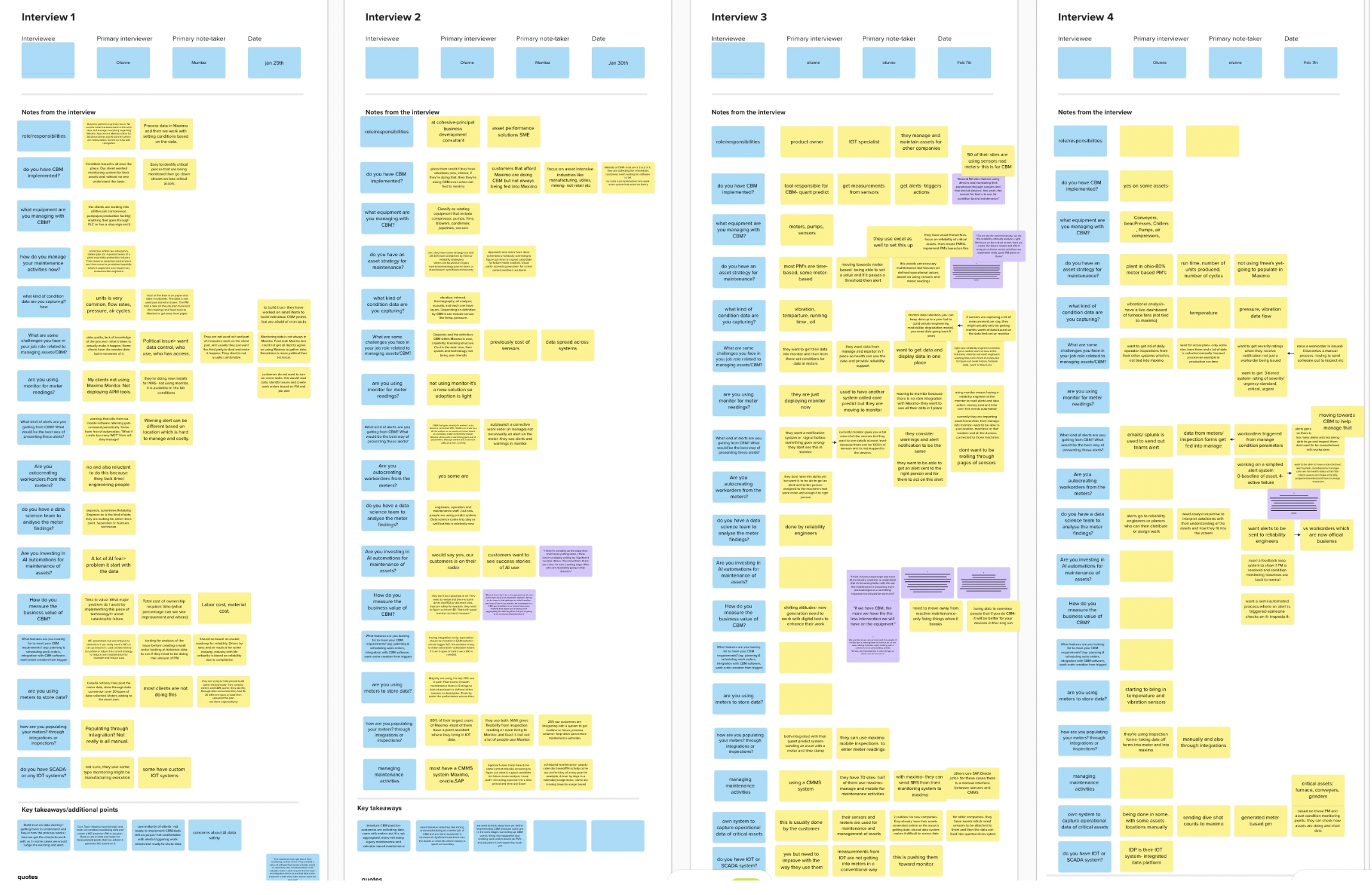

To uncover how different professionals experience CBM implementation, I interviewed 16 participants spanning four industries- this included people in Oil & Gas, Energy & Utilities and manufacturing. Some were Maximo customers and business partners and some were third-party participants.

Each brought a unique lens to the conversation; from the technical expertise of IoT Specialists and Maximo Administrators, to the strategic oversight of Operations and Maintenance Managers, to the risk-focused perspectives of Engineers and Product Owners.

Through these conversations, I discovered the challenges they face, the needs they prioritize, and the opportunities to deliver greater customer value by providing stronger support at every stage of the process.

During the interviews, I asked questions such as:

Are you manually or automatically collecting the asset data?

What kind of condition data are you capturing and how are you capturing it?

Are you using meters to store data. If so, how are you using them?

How are you populating your meters- is it through integrations or through inspections?

What are the biggest challenges you face in your job role related to creating an asset maintenance strategy and using CBM?

Summary of interviews

Interview analysis

After the interviews, I brought the insights into Mural, mapping out what we had heard to make sense of the diverse perspectives.

Patterns began to emerge; shared pain points across industries, recurring themes in their daily challenges, and clear opportunity areas where better support could make a real difference.

This synthesis became the foundation for shaping our next steps.

Interview analysis in Mural

“We want to make sure that we can connect our field data, operating data and tool data and then test data in one place and use that to drive the condition-based maintenance, because you need to understand the condition, right? It requires data.”

Next steps

The next step was to bridge the gap between what the product promised and what customers actually valued. Customers weren’t just looking for new features; they wanted proof of real business outcomes: saving money, saving time, and simplifying the way they managed their workforce.

I focused on reframing our messaging and design opportunities around efficiency. Rather than positioning CBM as another tool to learn, we needed to show how it could reduce their workload, not add to it. This meant prioritizing clear value communication, highlighting cost savings and faster time to value in ways that felt tangible to them.

At the same time, I kept in mind the realities of their context; smaller teams stretched thin, with years of institutional knowledge walking out the door as senior workers retired. Designing for adoption meant designing for relief: making the product intuitive, easy to use, and a true partner in managing limited resources.

By connecting these insights back to business value and customer reality, the next phase of research and design centred on building trust: testing clearer value propositions, simplifying onboarding, and validating that CBM could actually feel like less work, not more.

Business impact

By aligning CBM with customer realities, the business could drive stronger adoption and retention. Demonstrating cost savings and faster ROI helps position the product as a strategic investment rather than an added expense.

Simplifying workflows reduces resistance among understaffed teams, increasing willingness to adopt new tools. By supporting knowledge transfer as senior workers retire, the product becomes essential for long-term workforce resilience.

In short, the impact is twofold: increased customer trust and adoption on the user side, and greater market differentiation and revenue potential on the business side.